Physical Parameters

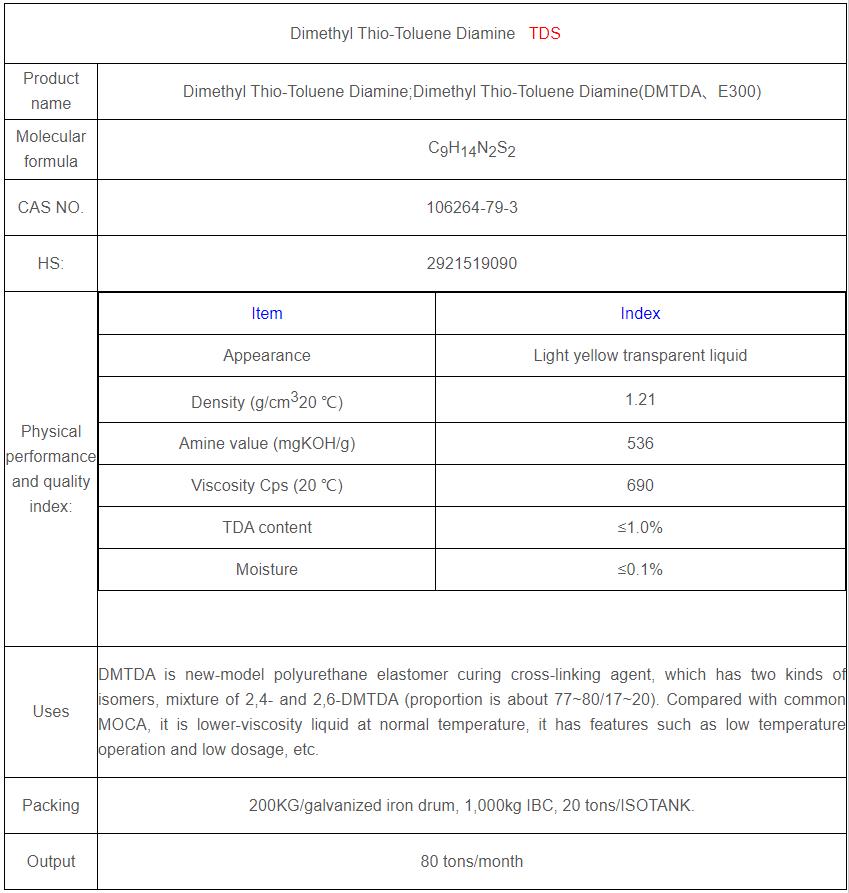

Dimethyl Thio-Toluene Diamine Basic Information

English name: Dimethyl thio-toluene diamine

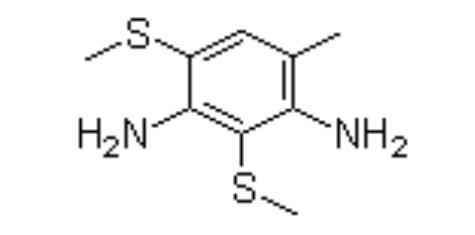

Synonyms: 3,5-Dimethylthio-2,4-toluenediamine; 2,4-Diamino-3,5-dimethylthiotoluene; dimethyl thio-toluene diamine; DMTDA; 1,3-Benzenediamine, 2 (or 4) -methyl-4 , 6 (or 2,6) -bis (methylthio) -; Ethacure 300; ETHACURE; 2 (or 4) -Methyl-4,6 (or 2,6) -bis (methylthio) -1,3-benzenediamine

Formula: C9H14N2S2

Molecular Weight: 214.36

EINECS Number: 403-240-8

Dimethyl Thio-Toluene Diamine(DMTDA) Physical And Chemical Properties

Appearance: Light Yellow Transparent Liquid

Boiling Point: 200 ℃ (1.68 MmHg)

Refractive Index: 1.659

Flash Point: 163.4 ° C

Density: 1.206

Water≤0.1%

Amine Value (MgKOH / G) 525-535

Color Value (Platinum-Cobalt-Method) ≤500

Dimethylthiotoluenediamine (2,4-Plus 2,6) Content% ≥96.0

Dimethyl Thio-Toluene Diamine(DMTDA) Export Cargo Security Data

CAS No.:106264-79-3

Hs:29309090.90

Hazard Class: 9

Tax Rate (%):13%

Un:2810

Dimethyl Thio-Toluene Diamine(DMTDA) Raw Materials:

Toluene Diamine (TDA) And Dimethyl Disulfide (DMDS)

Production situation:

The product yield: 80 tons / month

Shipping Port: China ShangHai

Price offer is valid: 15 days

Jincang time: 15 days (commodity inspection)

Export rights: the right to import and export company

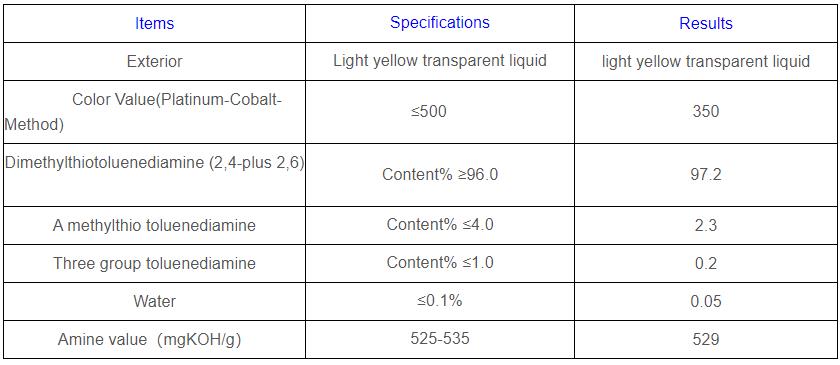

Product Index:

Dimethyl Thio-Toluene Diamine Uses:

Dimethyl Thio-Toluene Diamine(DMTDA) is a new polyurethane elastomer cured crosslinking agent, which is equivalent to Ethancure 300 mainly 2,6-thio-toluenediamine mixture of two isomers i.e., 2,4- and (ratio of about 77 ~ 80/17 ~ 20), compared with MOCA commonly used at room temperature is low viscosity liquid, it can be applied to construction operations, chemical use and low equivalent at low temperatures. DMTDA is an environmentally friendly low-toxicity liquid type diamine chain extenders, mainly used for polyurethane elastomers, RIM (reaction injection molding), SPUA (spray polyurea elastomer) and adhesives; also be used as an epoxy resin curing agent, has been widely used in polyurethane rubber roller, medical, stamping, etc. in addition, it is in the automotive, construction, mining, metal mining, textiles, paper, printing industry has a wide range of applications. DMTDA curing rate is much slower than DETDA, with DETDA mixed in different proportions to regulate the curing speed to meet different needs.

Dimethyl Thio-Toluene Diamine Instructions:

Dimethyl Thio-Toluene Diamine(DMTDA), because a liquid at room temperature, so the operation has significant benefits, such as the transfer easier and MOCA solid melting process will be eliminated. Similarly, the possibility of solidification does not occur in a mixing vessel or mixing machine inside. Furthermore, it is in a liquid state, allowing operation at a lower temperature than the MOCA. DMTDA equivalent is 107 compared with MOCA is 133.5, which means that the same given under stoichiometric prepolymer can be reduced 20% by weight of the amount of use. For instance:

Prepolymer (NCO 4.1) 100 parts 100 parts

MOCA (95% of theory) 12.4 parts -

DMTDA (95% of theory) 9.9 parts

Total 112.4parts 109.9 parts

Dimethyl Thio-Toluene Diamine(DMTDA) specific gravity of about 1.20g / cm3, Recommended temperature 70-90 ℉ (21-33 ℃), and the use of temperature 240 ℉ (116 ℃) melted MOCA proportion of 1.26g / cm3, which means that the volume of use Both pumps transport raw materials without changing the existing mixing equipment case, to achieve the above object need to use ratio instead DMTDA MOCA use ratio.

Dimethyl Thio-Toluene Diamine(DMTDA) physical properties of curing agents of polyurethane elastomer: the physical properties of the prepolymer, including polyester and polyether type, with DMTDA cured, and cured compared with MOCA; as with MOCA curing systems, pre Physical properties of the cured polymer ideal ratio is sensitive, DMTDA curing agent compared with MOCA, to stoichiometric exhibit acceptable deviation stoichiometric low (80-90%) is usually obtained as helpful maximum permanent deformation resistance to compression rate, and high stoichiometry (100-105%) helps to get the maximum value such as tear strength and fatigue life. For best results when most uses is 95% of the ideal ratio. (DMTDA curing conditions (temperature and time) and MOCA similar, but more emphasis needs DMTDA secondary vulcanization conditions to obtain optimum physical properties, particularly compression set and dynamic mechanical properties.

Production Process

Dimethyl Thio-Toluene Diamine(DMTDA) Process Is As Follows:

① First Cast In The Vessel A Certain Amount Of TDA, Was Heated To Above 120 ℃, The Addition Of A Catalyst, Then Dropping A Predetermined Amount Of DMDS At 120 ^ 130 ℃, Keeping Reflux. Sampled For GC Analysis To Determine The Extent Of The Reaction Is Carried Out To Remove Excess DMDS Reached The End, To Give The Crude Product.

② The Crude Product Was Dissolved In 5% To 15% Hydrochloric Acid, N (HCl) N (DMTDA) = (1 ^} 3) No.21, Then Filtered, Residues Activated

It Can Be Used As The Main Catalyst Recycling; The Filtrate Was Added To The Alkaline Soda And The Oil Phase Was Separated And Washed With Water And Dehydrated To Obtain The Product.

③ Process Tail Gas Sulfur, NaOH Solution To Absorb The Oxidation Of DMDS, Aqueous Phase Is Separated And Treated With Naz C03, Crystallization, After The Filtration Cycle; Oil Phase Was Made After Refining The Raw Material Is Recycled Back Through The Main Process.

Small Scale Synthesis Cycle Of The Reaction Is 7 ^ -8 H, The Test Synthesis Cycle 9 ^ -10 H, Methyl Mercaptan By-Product Of The Oxidation Can Be Converted To DMDS Recycling, Not Only Reduces The Cost Of The Process, But Also Reduce The Environmental Load. Wastewater Discharge In Full Compliance With National Emission Standards, And The Filtrate Was Used As A Catalyst Activation Treatment Cycle.

By The Relevant User In The PU Elastomer Trial Production, The Resulting Product Performance And Sample MOCA Rather, Some Indicators Also Increased Slightly.

Packing

Packing: net weight 200KG / galvanized iron (a small cabinet loaded 16 tons a child care), 1000KG / IB barrel (a small cabinet loaded 18 tons) or 23 tons ISOTANK.

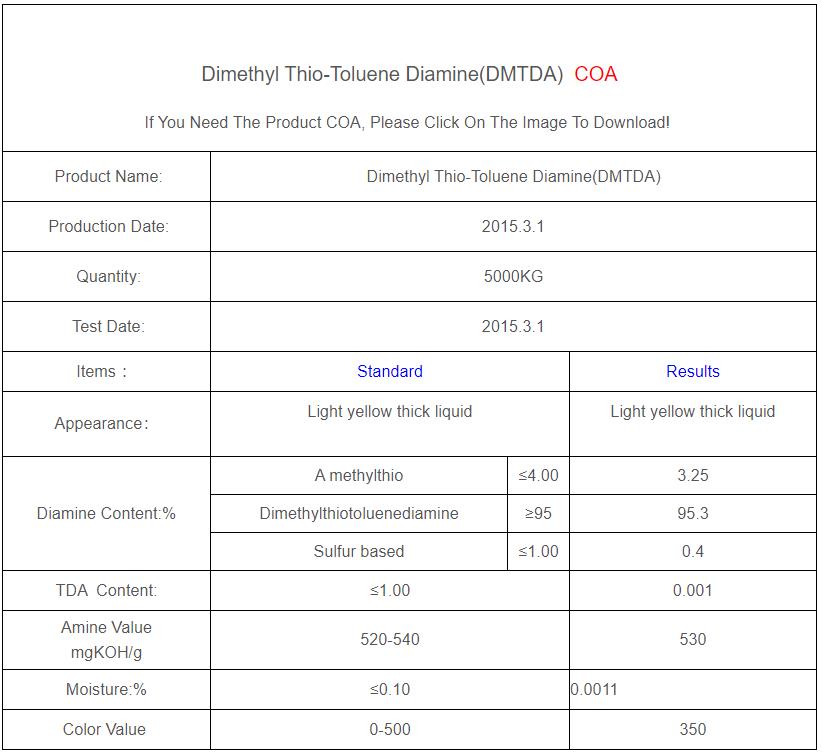

COA

TDS